ATV Winch Won’t Work – The Ultimate Troubleshooting Guide

Page Contents

This guide is made to help you troubleshoot the most common ATV winch issues. It will also point you in the right direction on how you should go about fixing them.

ATV winches are tough. They can handle incredible amounts of use and abuse. And as long as you steer clear of the cheapest models, and you treat it well with some maintenance now and then, you should expect many years of hassle-free winching.

But from time to time, even the best will face some technical issues that need to be addressed.

Luckily, there is a lot you can do yourself to troubleshoot and repair an ATV winch that doesn’t work as its supposed to.

Important safety note

ATV winches are small but still powerful and potentially very dangerous. If you have any doubts or lack the basic mechanical skills to perform the troubleshooting or repairs described in this post, you should rather take it to an authorized dealer and let them take care of it for you.

A winch out of control has the potential to inflict damage to your equipment or possible cause severe injury to yourself or others.

How this guide works

I’ve structured this guide so that you can start your troubleshooting based on what symptoms you are experiencing. After all, that’s how it starts; suddenly the winch will start behaving differently than it should.

This will lead you to the root of the problem much faster than by just randomly testing all the different things that can go wrong.

For many of the symptoms, there are several possible causes, and some causes may give several types of symptoms.

After you have determined what’s causing your problem, you’ll find a suggested solution to the issue.

The winch is completely dead

With the engine running, you push the winch switch but nothing happens. The winch motor is not turning. Not even making a click or a buzzing sound.

The fastest way to troubleshoot a winch that is not giving any sign of life is by isolating the problem.

Before you spend too much time investigating other possible causes it’s a good idea to determine whether the problem is with the winch itself or with the wiring.

To do this, you simply need to perform this quick test:

The Jumper cable test

This test will bypass all of the wiring and other electronics and will tell you if the winch motor is working or not.

Test the winch motor using starter cables.

- Disconnect all winch cables from the bike.

- Disconnect the battery from the bike, or use another battery so that you don’t damage the bike’s electronics.

- Connect the jumper cables to the battery. Polarity does not really matter for this test, but red to + and black to – is always a good starting point.

- Connect the negative cable to one of the terminals on the winch.

- Gently tap the other terminal using the positive cable. This is done to make sure the winch does not have a dead short. The drum should move slightly. If it does not, stop the test at this point. Some sparks when tapping like this is normal.

- If the drum moved slightly when tapping, attach the positive terminal completely. The winch motor should operate as normal in one direction.

- Then repeat the test by switching the cables on the winch. The motor should then move freely in the opposite direction

Now you should know what causes to look at for further troubleshooting.

Cause: Blown fuse or tripped circuit breaker

Some winches, but not all, have a circuit protector or a fuse that is meant to blow when the winch for some reason is pulling too much power. A circuit breaker may also trip if it gets submerged in water.

Suggested Solution: If the fuse is blown, replace it with a new one that has the correct amp rating.

Suggested Solution: The circuit-breaker may need to be reset manually if it’s been tripped.

If the winch starts working again, you have fixed the problem.

If the new fuse blows again right away or the circuit breaker trips, you likely have a short somewhere.

A short happens when the positive (red) cable gets in contact with any metal part, like the frame of the bike, due to a damaged cable. A faulty switch may also cause a short.

Suggested Solution: Repair or replace any damaged cables or broken switches that’s causing the short.

If you can’t find any shorts in the wiring, the short may also be inside the winch itself or in the contactor. More on that further down.

Cause: Improper or bad wiring

A completely dead winch often indicates that it’s not getting any power, or that something is not grounded the way it should be.

Suggested Solution: Make sure the winch is wired correctly.

If it has been working correctly before and you haven’t done any modifications to the wiring, an incorrect installation should not be what’s causing your issue.

But if you’re in the process of installing a new winch now, and you can’t get any sign of life, it’s a good chance you’ve got the wiring wrong somewhere.

All winches should come with a complete wiring diagram. Make sure you follow it to the point!

The basic principles on how to do the wiring should be the same on any winch. But it’s worth noting that you will see some minor but important differences between the different brands.

It’s common that the battery terminals on the contactor have different setups, where connecting the wires wrong may lead to a dead winch.

When the winch has been installed on the bike for a while, the cable terminals may corrode or come loose.

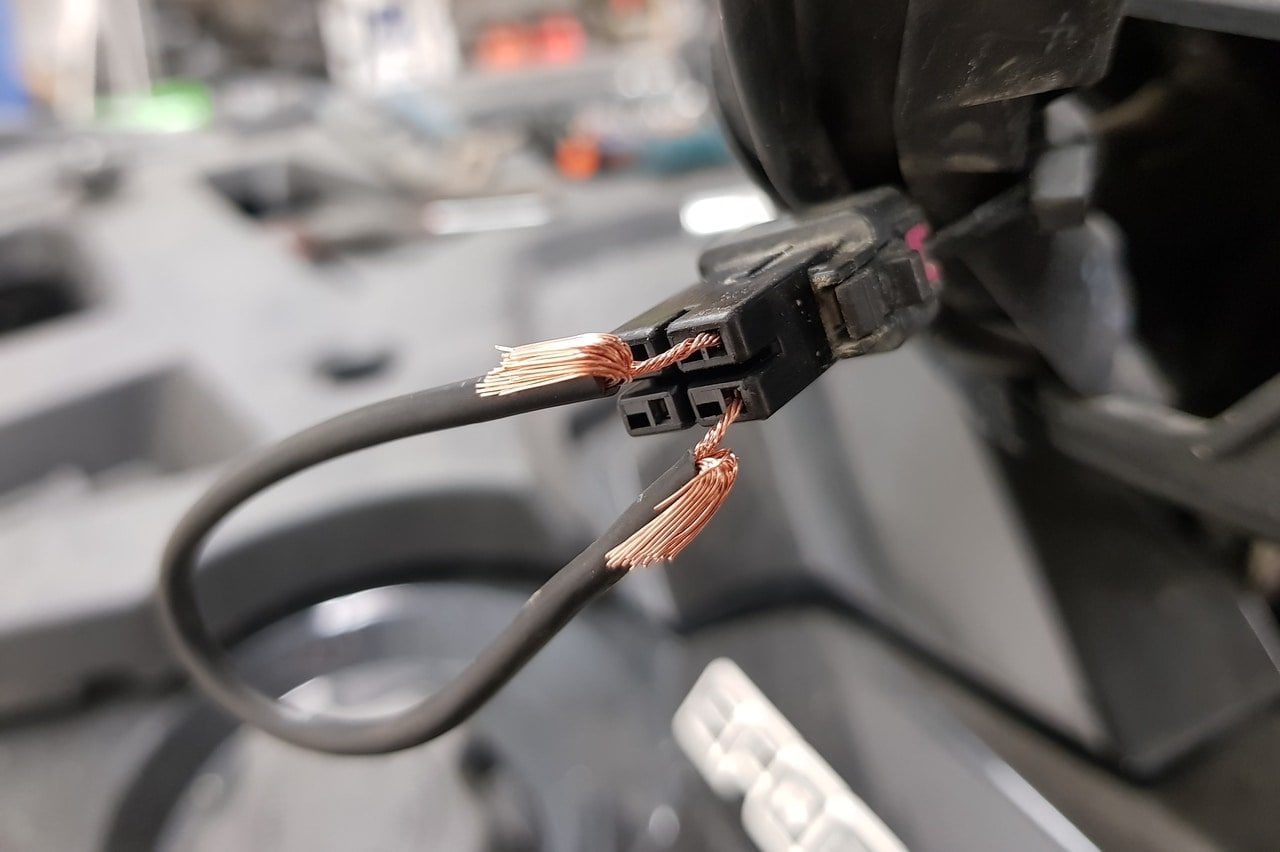

Winch cable connector that’s slightly corroded.

Suggested Solution: Dissasemble and clean all terminals, one by one to make sure you have good connection everywhere and that they are properly fitted. Any corrosion can be removed with some sandpaper so that the terminals become shiny again.

Cause: Defect handlebar rocker switch or remote switch

Any switch can break due to material fatigue when it’s been pushed enough times. Cheaper winches usually come with less robust switches that will break sooner.

It may also stop working due to water entering and corroding its internals. Again, the cheaper ones are often less protected and are more likely to be acting up after a few encounters with salt and water.

If a switch is damaged or corroded, it may not engage the winch at all when you push it.

There are several ways you can go about troubleshooting a bad switch:

Test if other switches work

If the bike has more than one switch to activate the winch, you should begin by testing them both to see if one of them work.

Wireless remote and remote rocker switch.

It is very unlikely that both switches will fail at the same time. If one works, but you get no reaction from the other, it has likely gone bad.

Bypass the switch

If you have only one switch you can determine if it’s defected by testing if the winch works when you bypass the switch:

Bypass the remote switch to make sure it’s not what’s causing the issue.

- Start by disengaging the winch by putting the engage lever in the free spool position. You don’t want the winch to be doing any actual winching when performing this test. You only need to see if the winch engine is starting or not.

- Disconnect the remote switch plug from its socket.

- Use a short piece of wire to “jump” two of the opposing four (or three) pins. This wire is called a jumper lead, any piece of wire should work (16 gauge and up). The motor should now start.

- Then try jumping the two other pins. The motor should now start and turn the other way.

- If the winch motor starts and runs in both directions when performing the test, the switch itself is likely faulty.

Suggested Solution: Replace the damaged switch.

Cause: Faulty or dirty winch motor

If none of the above resolved your issue, and the system is simply just dead silent even when performing the jumper cable test, you are likely facing some sort of issue with the winch motor itself.

The voltage drop test

Another way to test the engine is by reading voltage drop across the motor. You need a multimeter to do this test.

- Set multimeter to VDC (volts, direct current)

- Use some tape or alligator clips to connect the multimeter directly to the winch. One to the grounding and the other to the blue or yellow cable. Polarity does not really matter in this test.

- Turn the key on and push the remote switch.

- The reading should be close to or above 12V. If it’s not, it’s a good indication that something is not right within the winch motor.

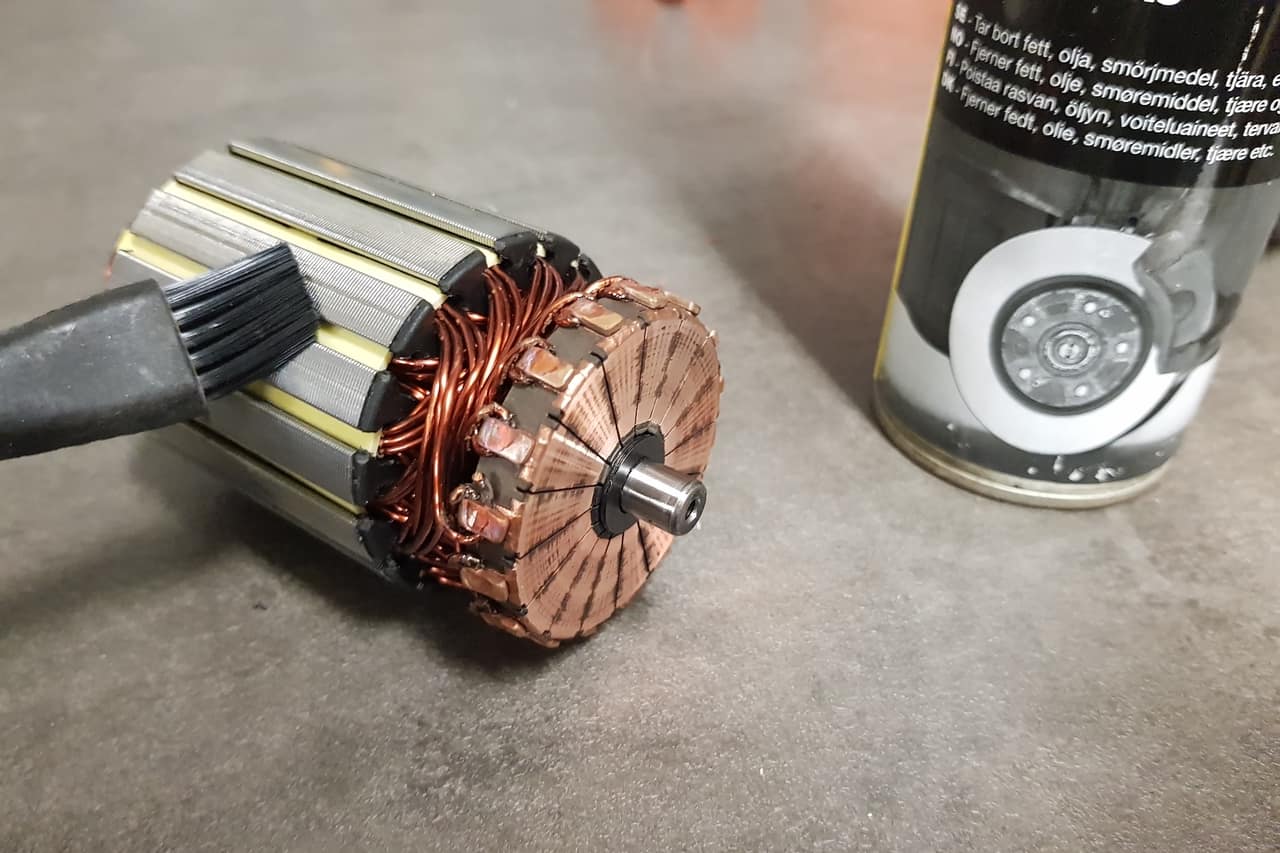

Possible Solution: Clean the motor. The electric motors inside winches are actually quite simple and robust. But they are not completely fail-proof. And sometimes dirt may enter the motor housing, creating a dead short.

Disassembling the motor and giving it a good clean may be all that it takes to bring it back to life.

Use brake-clean to clean the winch motor.

- Remember to turn off the key and remove the battery terminals before you do any work on the winch.

- With the motor disassembled, spray the motor itself thoroughly with brake clean and gently rub it with a toothbrush or copper wire brush.

- Also, clean the inside of the housing.

- If you have an air compressor available, use it to blow off any debris.

Make sure it is dry before you assemble and test it again.

If cleaning does not help, it may have a burnt coil or a short in the motor armature. This may happen if you wire the winch incorrectly or if it’s been overheated.

Possible Solution: Replace or repair the damaged motor. If the motor is damaged it may need replacing, or a complete rebuild performed by a specialist.

Cause: Worn or damaged brushes

The brushes will wear over time, or they may become damaged from damaged armature commutator.

Suggested Solution: Replace worn or damaged brushes. If the motor has some age to it, the brushes may be worn and need replacing. And if the motor armature gets damaged, it may also damage the brushes.

- Open the motor housing and inspect the motor.

- Look for burnt spots or wear in the brushes. If they look worn compared to new ones, they are relatively easy to replace.

Brand new winch motor brushes.

The winch motor turns in only one direction

If when you engage the winch, either by using the handlebar rocker switch, or a wired or wireless remote, the winch motor will turn just one way.

It may spool in, but not out again, or it may spool out, but without being able to spool it back in.

Before you spend time and money on more expensive parts, it’s a good idea to make sure the problem is not in the wiring, as these kinds of issues are usually cheap and simple to repair.

Cause: Improper or bad wiring

Again, the cause of the issue may be some sort of wiring issue.

But before you check the rest of the wiring as described above, you should start by having a look at the cable that goes from the remote switch to the contactor.

The cable itself may be damaged, or the connector at the contactor may have come loose.

Also, check if the pins inside the remote control plug have become pushed out of position or bent.

Suggested Solution: Repair or replace any damaged wiring.

Cause: Defect handlebar rocker switch or remote switch

If the switch is only partially defect, the winch may not go completely dead but can work in only one direction. Test the switches as described above to see if they are all working properly.

Cause: Defective, rusted or stuck solenoid

If you’ve ruled out that the problem is not in your wiring, you will likely find it in the solenoid inside the contactor.

What are a contactor and a solenoid anyways?

You can compare the contactor to an ordinary relay. They have the same purpose: To prevent having to send all of the current directly through the remote switch, which would require a very impractical huge switch.

The contactor is basically a huge switch that can handle high currents. It’s activated with a low current from a much smaller switch.

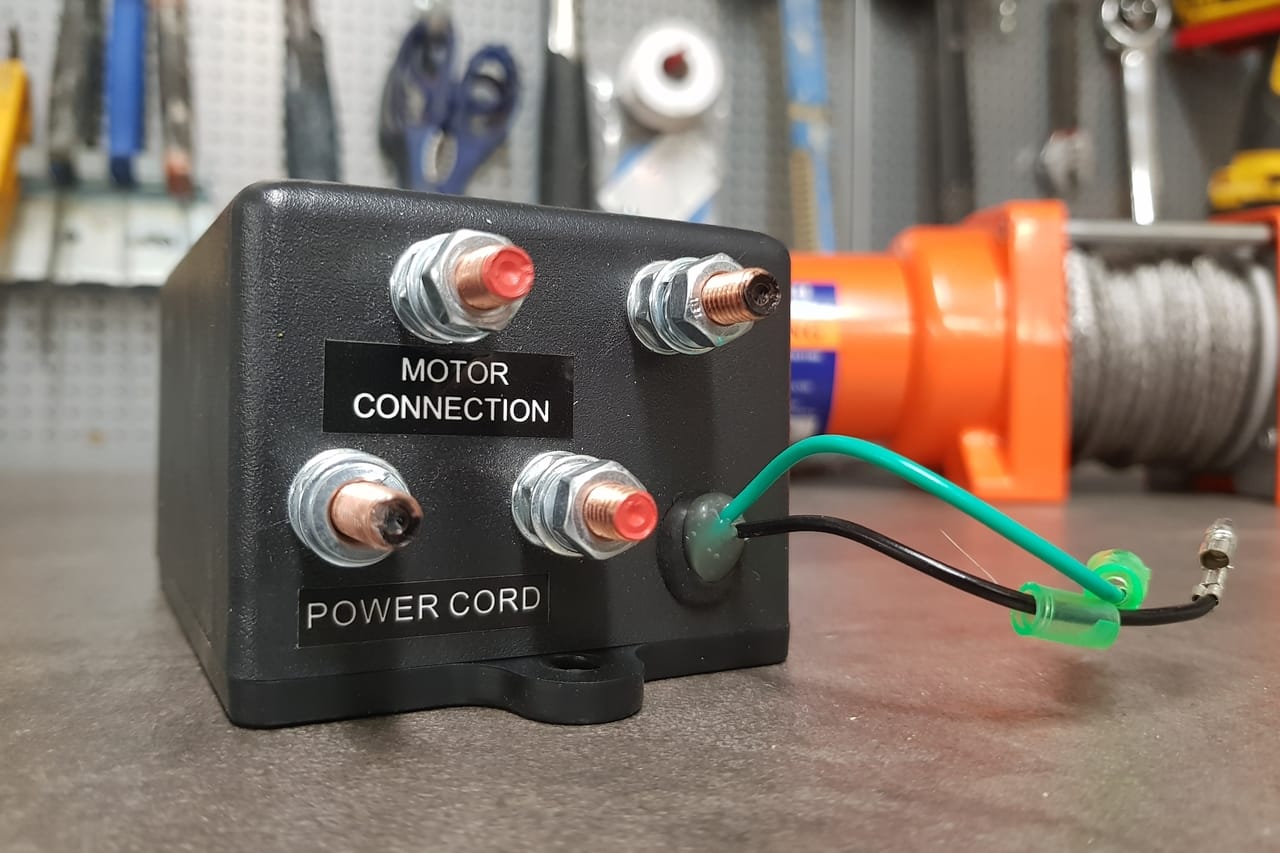

This contactor uses only black and red color coding. Others use yellow and blue as well.

All ATV winches will have one, and its job is to switch between sending positive and negative electric current to the winch. This is what determines which way the engine turns.

Inside the contactor, you’ll either find one two-sided, or two single-sided solenoid magnetic coil switches. One is activated when pressing the in button, and the other is activated when pressing the out button.

When the solenoid works as it should it will physically move when it’s being activated. This is what makes the audible clicking sound when you activate the winch switch.

A two-sided solenoid will have four battery cable connections, where one side is wired + to – and the other side is wired – to +. These are often marked with the colors red, black, blue and yellow, matching the wires that go on them. Some winches use only red and black color coding.

Solenoids do, however, tend to break or get stuck. When it’s stuck you won’t get it to switch between positive and negative current.

Suggested Solution: You can try gently tapping the contactor with the handle of a screwdriver to free it up. But this will just be a temporary fix. It may soon get stuck again until you replace the contactor for a new one.

Because of the wet and muddy conditions that lead you to get a winch in the first place, the solenoids may rust over time. Rusted plungers will not move freely so that you don’t get proper contact.

When you take off the contactor cover, you will quickly see if corrosion is what’s causing your issue.

Suggested Solution: Replace rusted contactor.

Solenoid test

You can test the solenoid by hooking a test light on the cables that go to the winch.

Test first with the blue, then with the yellow. If you don’t get a light with one of them, you likely have a bad solenoid.

A good way to protect your new contactor is by slathering it with dielectric grease and make sure it’s placed up high and dry.

The contactor is clicking, but the winch doesn’t work

This one is very common and when it comes to troubleshooting, it has a positive side to it:

When you hear an audible click sound you know that the contactor is getting power when the switch is being pushed. This means that everything up to the contactor, including the switch should be fine.

Cause: Battery is defective or not fully charged or battery terminals are corroded

Suggested Solution: Start by making sure the battery is fully charged and has a voltage reading of at least 12,4V. Remove the battery terminals and clean them to assure a proper connection.

Also, make sure that the grounding cable on the winch motor housing is properly fitted.

This leaves either the winch motor or the contactor.

When you are in a situation like this, you want to rule out one or the other. Again, the easiest way to go about doing this is by performing the jumper cable test as described above, to see if the winch is working or not.

Cause: Contactor is damaged or corroded

If the winch works as normal when you power it with jumper cables, the issue will very likely be in the contactor.

The solenoids may be firing up, but they are not connecting. This may be due to corrosion or damage from overheating.

Suggested Solution: In this case, the contactor needs replacing.

Cause: Faulty or dirty winch motor

If the motor does not turn as normal when being fed power directly from the battery, you know it has some sort of issue.

The possible causes to it not working, and procedures for troubleshooting and fixing are exactly the same as when the winch is completely dead.

The winch works sometimes, but other times it doesn’t

If the winch works fine sometimes, but other times it just makes a clicking sound, the cause of the issue will likely be the same as when you always get clicking and the winch never works. Just follow the steps above, and you should find your problem.

If the winch works sometimes, but other times is completely dead, you are more than likely facing a loose cable, creating a bad connection somewhere. Go over the wiring, and make sure nothing has come loose.

The winch turns very slow or lacks power when pulling

You may find that the winch turns but does so very slowly. It seems to seem to be down on power or will even stall when pulling loads it normally should manage just fine.

This may be due to a damaged motor as described above where you just get a clicking sound. Other possible causes are:

Cause: Winch cable or rope is spooled onto the drum in the wrong direction

If the cable or rope for some reason is not spooled onto the drum in the correct direction, it will work against the automatic brake. This will be like trying to drive your car with the handbrake on.

Suggested Solution: Spool the cable or rope all the way out, and re-install it in the correct direction. There should be a sticker indicating correct drum rotation.

Cause: Insufficient battery power

Suggested Solution: Fully charge the battery. Replace it if the battery is damaged. Clean terminals.

If the battery keeps draining, even if you have charged it, it may be due to issues with the bikes charging system. In this article I have I take a closer look at this and many other reasons to why an ATV battery keeps draining.

Cause: The grease used inside the winch gears is old, gummed up or full of dirt and water.

Suggested Solution: Please refer to the procedure for re-greasing the gears when the winch won’t free spool.

Cause: Too much, or old grease in the gears

If you put too much grease in the planetary gears, have used the wrong grease (too thick) or if the grease has gummed up due to water contamination and age, the gears will not turn as freely as they should.

Suggested Solution: Remove old grease, apply correct amounts of new grease.

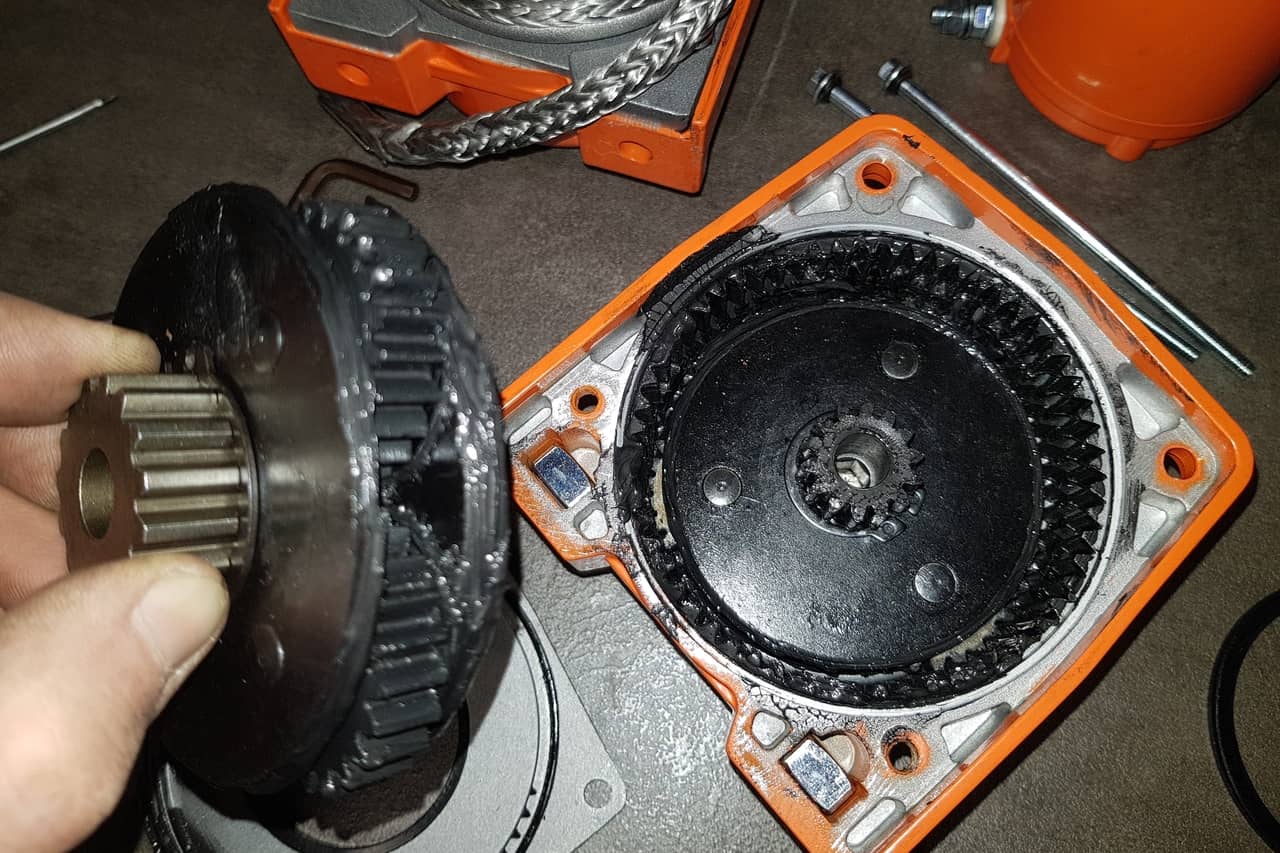

Brand new planetary gears with factory grease.

- Disassemble the winch and gears. Take photos underways to remember where everything goes. The planetary gears themselves do not come apart.

- Put the gears in a tub of degreaser for some hours.

- Finish cleaning odd old grease using a toothbrush or similar.

- Get some CV joint grease or some other grease with a relatively thin consistency.

- Wear a rubber glove and use your finger to apply a nice even but not a too thick coating on every gear except the sliding ring gear.

- Also, grease the bushings at each end of the spool.

- Reassemble everything.

The winch spool is stuck

If your winch cable has become all jammed up and goes in no matter which way you run it, this little trick may get you out of a pinch.

- Get the winch to the point where the jam prevents it from unwinding.

- Wrap the winch cable around a solid object a tree or the bikes own bumper and gently run the engine for the jam to release.

This works most of the times. Others it just makes the situation a lot worse.

Another tip is to put the winch in a free spool position and use another winch to pull it out.

The winch motor gets very hot very quickly

While some heat is normal whenever the winch motor is being put under a heavy load, you may find that it gets abnormally hot after being used for a short amount of time.

Also note that operating the winch over a long period may also overheat it, with the risk of permanently damaging the motor. Take breaks to allow the motor to cool down.

Cause: The bushing that sits in the winch motor end cap is too tight

Suggested Solution: Remove the winch motor end cap. Use some fine sandpaper or emery cloth and give both the motor end shaft and the inside of the bushing a light rub.

Cause: Damaged winch motor due to incorrect wiring or previous overheating from pushing it too hard

Suggested Solution: Replace winch motor.

The winch won’t engage or disengage

The motor may be turning, but you cannot get the winch to engage. Or you may have problems getting the winch to disengage to the free spool position.

When the engage lever will not budge, the problem can be with the knob/ lever itself, or with the gears, it operates.

Cause: Stuck engage lever due to corrosion or debris preventing it from spinning freely

Suggested Solution: Clean, remove rust and apply new grease

The lever needs to come out so that it can be cleaned and any rust must be removed. Some levers can be removed without disassembling the winch.

- Simply remove the bolt holding the lever in place, and wiggle the lever out.

- Clean it, and remove any corrosion using some fine sandpaper.

- Apply some grease and reinstall.

Other winch models require some disassembly for the lever to come out.

- Take off the winch cover.

- Remove the bolt that holds the spring-loaded detent ball in place.

- Wiggle the whole lever out and give it the same treatment as described above.

Now that your winch is already disassembled, it may be a good idea to service the gears while you are at it.

Cause: Sliding ring gear won’t operate due to dirt, corrosion or grease

Suggested Solution: Clean and remove corrosion. Apply oil.

Inside the winch, on many models, there is a ring gear that needs to slide freely sideways for you to be able to engage and disengage the winch.

If this gear or the outside diameter of the winch housing that slides up against starts to corrode, it will become stuck either in the engaged or disengaged position.

Dirt and other debris won’t help the situation either.

Disassemble, clean, remove rust, lightly coat gear and housing surface with oil and reassemble.

It may also be hard to get this ring gear to slide if someone mistakenly has applied grease on the outside of the gear, or to the inside of the gear housing.

While the other winch gears should be lightly greased with some CV-joint type grease, this is not true when it comes to the ring gear.

The grease will create too much drag, making the gear hard to operate. A light coat of oil is all that should be used here.

Cause: Mechanical gear failure

If the gears have become damaged in some way, you may not be able to budge the engage lever at all. Using the winch to tow someone, or trying to yank on someone that’s stuck, is a common rookie mistake that is likely to strip the gears.

Suggested Solution: Replace damaged gears.

You need to disassemble the winch and inspect for damaged gears. All damaged parts can be replaced to get the winch back in working order.

Cause: Warn: Stuck twist style end-knob

Warn and many other ATV winch manufacturers use a design where you need to twist a knob at the end of the winch housing to switch between free-spool and locked position.

This design, however, seems to be a bit more fragile than the angled knob often seen on larger winches. Some models have issues with the knob getting stuck due to bad design.

What happens is that the knob gets stuck when it is over-rotated and the clutch bar gets hung up on a small plastic sliding ramp that’s part of the design.

You can disassemble the knob to put everything back in place, but if your winch is affected by this issue, you will soon get it stuck again if you are not careful

Suggested Solution: Get upgraded parts from the manufacturer.

If you are facing issues with engaging or disengaging a winch that uses this type of knob I suggest taking it to the dealer to get upgraded replacement pars if it’s still under warranty.

ATV winch won’t free spool or is very difficult to free spool

Even if you managed to get the winch to disengage properly, it very hard to free spool. It requires a lot of force to pull out the cable/rope.

Cause: Burr on the sliding ring gear, creating drag against the inside diameter of the gear housing

If you engage or disengage the winch under load it may create a burr on the outside of the ring gear. This creates mechanical friction and makes it harder to free spool the winch.

Suggested Solution: Use a file and gently remove any burr. Apply oil before reassembling.

Cause: Grease on the sliding ring gear

The sliding ring gear and the inside diameter of the winch housing that it slides against should not be greased.

Not only does this makes it hard to engage the winch, but it will also create drag, making it hard to free spool the winch.

Suggested Solution: Remove grease, apply a thin layer of oil.

Cause: Bent flanges on the winch drum

If you winch at an angle, all the cable will stack up on one end of the drum.

This may not only get the drum stuck, but it may also damage the drum itself by forcing the sidewalls outwards.

Disassembled winch drum.

Suggested Solution: Disassemble and try to straighten the drum walls. If it cannot be repaired, the drum needs replacing.

The winch is slipping under load

Cause: If the winch is slipping, this may be due to the clutch not engaging properly

Suggested Solution: Try troubleshooting why it won’t engage as described earlier.

Cause: Stripped gears

Whether it is due to using the winch the clutch not being completely engaged, or from incorrect use like towing or yanking, the gears may be stripped.

Inspect all of the winch gears.

Suggested Solution: Disassemble the winch to inspect the gears, and replace them if needed.